-

> English > Products > Sealing test

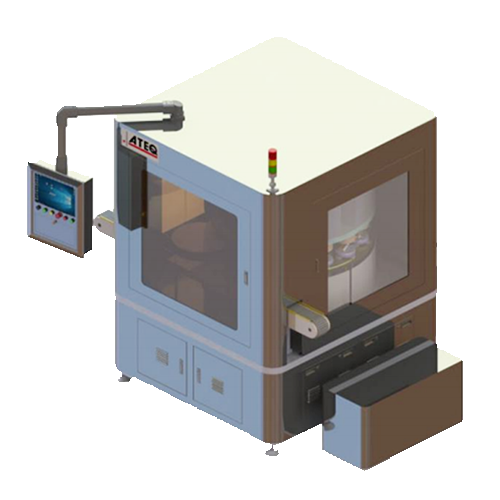

BFS online vacuum attenuation testing method

Background:

According to relevant regulations and policies, the sealing of sterile drug packaging containers should be verified to avoid product contamination. Fused sealed products (glass ampoules or plastic ampoules) should undergo 100% leak testing.

Product features:

1. Use vacuum attenuation method for testing, with a test pressure of 5mbar absolute pressure

2. Single station testing time: 10s

3. Detection speed: 40 sets/min

4. Loading and unloading on the assembly line

5. Reference standard: ASTM2338-09

6. Comply with GMP industry standards

7. Automatic storage of equipment testing data for easy traceability and query

In order to ensure testing efficiency and meet the requirements of online workpiece inspection, a turret testing mechanism is specially adopted.

Equipment parameters:

project | parameter |

Device Name | Ampoule bottle leakage testing equipment |

Overall dimensions | 2000 (W) * 2000 (W) * 2200 (H) |

Device Functions | Testing the leakage of ampoule bottles |

Workstation | 15 workstations |

Loading and unloading methods | Loading and unloading on the assembly line |

UPH | 2400 sets/H |

Testing instruments | ATEQ LPV |

Instrument accuracy | ± (1% raderin+1Pa) |

test method | Vacuum attenuation testing method |

Test air pressure | Absolute pressure 5mbar |

power | 5KW |

source | 220VA, 50HZ |

Usage environment | 45%~65% humidity, 22℃± 2℃ |

Air source | 0.6MPar 90L/min |

Product Introduction:

1. Use a fully enclosed stainless steel sheet metal cover to effectively prevent secondary pollution and corrosion;

2. The inlet and outlet assembly lines are made of plastic chain materials to prevent equipment damage or secondary pollution caused by chemical corrosion of subsequent products.

3. Use 15 station turret mode, action flow, and no waiting time.

4. A storage box for NG products is designed, and NG products are uniformly recycled.

5. The action control adopts PLC, and the testing data collection adopts the upper computer. Professional customized interface, maximizing compliance with customer production requirements.

Principle of online vacuum attenuation testing:

Firstly, place the medicine bottle in a sealed chamber inside the equipment and apply a vacuum, which will cause the gas inside the medicine bottle to overflow through a leakage pathway. If liquid drugs are placed in the medicine bottle, when the vacuum is lower than the liquid vapor pressure, the liquid in the leakage channel will vaporize. Therefore, the increase in air pressure in the sealed chamber is caused by the leakage of the pharmaceutical packaging. This pressure will be detected by one or more sensors in the sealed chamber.